flight Solutions for Aerospace

pSeven, with its Airbus roots, brings deep experience in Aerospace disciplines and associated engineering domains. For over a decade, we have helped commercial aircraft companies, engine manufacturers, tier-one suppliers and space market leaders to develop better products faster.

Aerospace industry leaders worldwide — Airbus, Airbus Defense & Space, Airbus Helicopters, ArianeGroup, Korea Aerospace Industries, Stelia Aerospace and others — apply pSeven products at various stages of aircraft development.

Adressing challenges

in the Aerospace industry

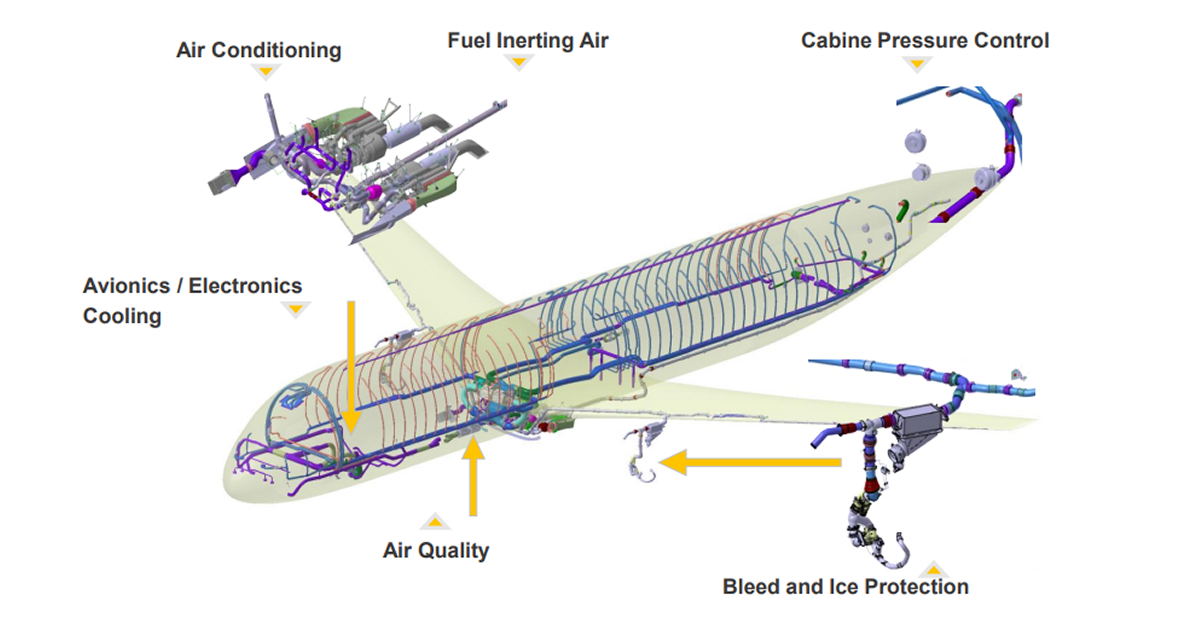

The aerospace industry faces significant challenges when it comes to balancing safety, costs and performance. Aerospace sector is well known for being one of the most rigorous and regulated market. Engineering activities deal with highly complex systems sometimes operating in extreme conditions, all within a demanding regulatory environment. As a result, companies must be at the forefront of innovative engineering methods and use cutting-edge software solutions to perform trade-off analysis in high-dimensional spaces.

pSeven products providing collaborative engineering capabilities, process automation, design space exploration and predictive modelling tools, enable multidisciplinary studies and rapid identification of optimal designs along with knowledge capturing and sharing at scale. These capabilities help aerospace companies overcome challenges and guide the industry toward a more efficient and sustainable future.

Balance performance

and regulations compliance

Concept stage

- Combine different models and data sources.

- Involve multiple physics.

- Estimate the impact of uncertainties.

- Run trade-offs studies.

- Optimize early in the design process.

Design stage

- Build fast ROM models using ML/AI to predict product behaviour in various conditions.

Democratize simulation

and improve collaboration

- Implement scalable methodologies: share simulation methodologies with other users across and outside of organization in a form of workflow-powered web apps.

- Improve collaboration within and between the teams with simultaneous multi-user access and co-authoring of the workflows in real-time.

Manage complexity

and digital transformation

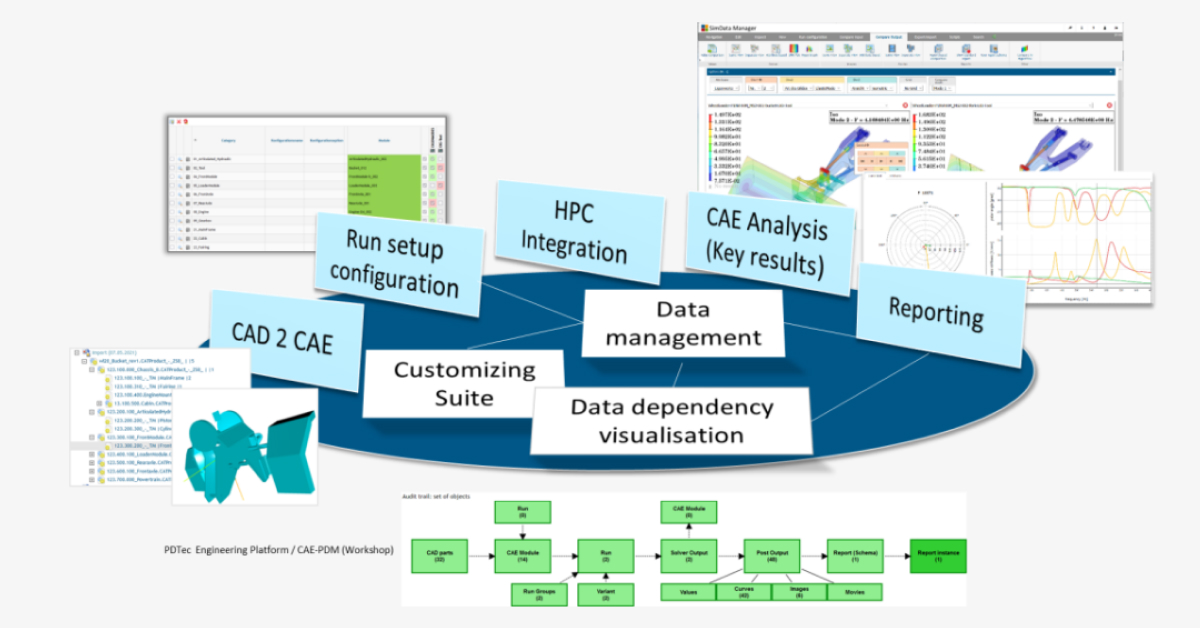

- Automate multidisciplinary engineering workflows and repetitive simulations.

- Boost PLM / SPDM systems with enhanced simulation workflow execution.

- Capture knowledge from vast amounts of data from simulations and experiments.

- Reuse engineering data.

- Ensure production, deployment, management of Digital Twins at scale.

Manage conflicting requirements and keep costs down

with Design Space Exploration

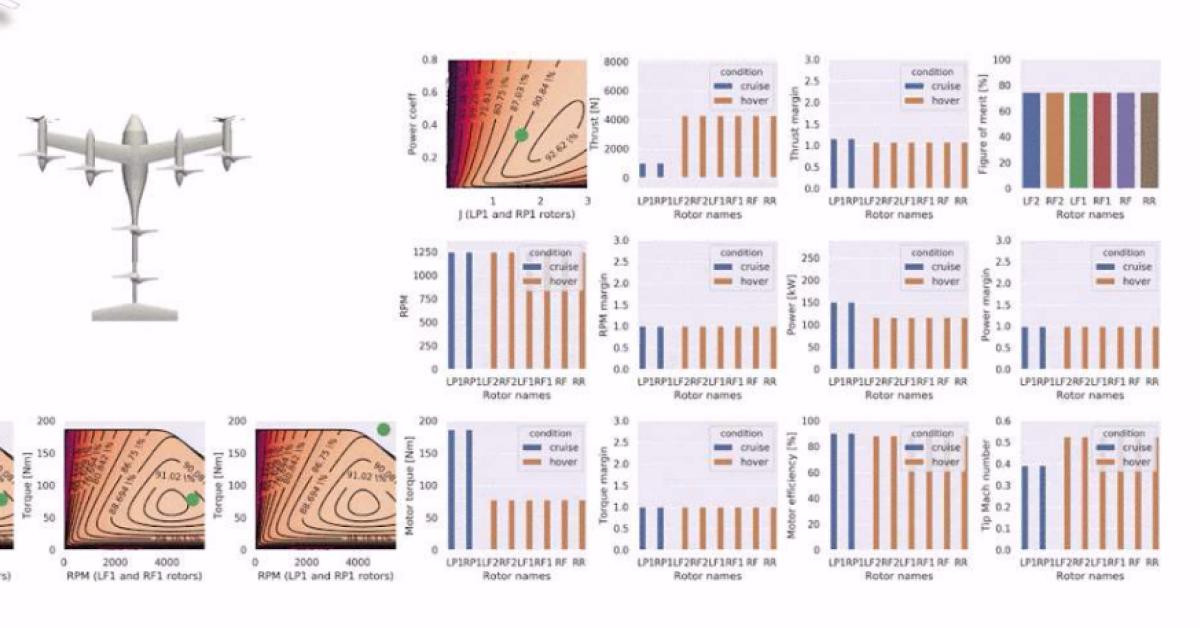

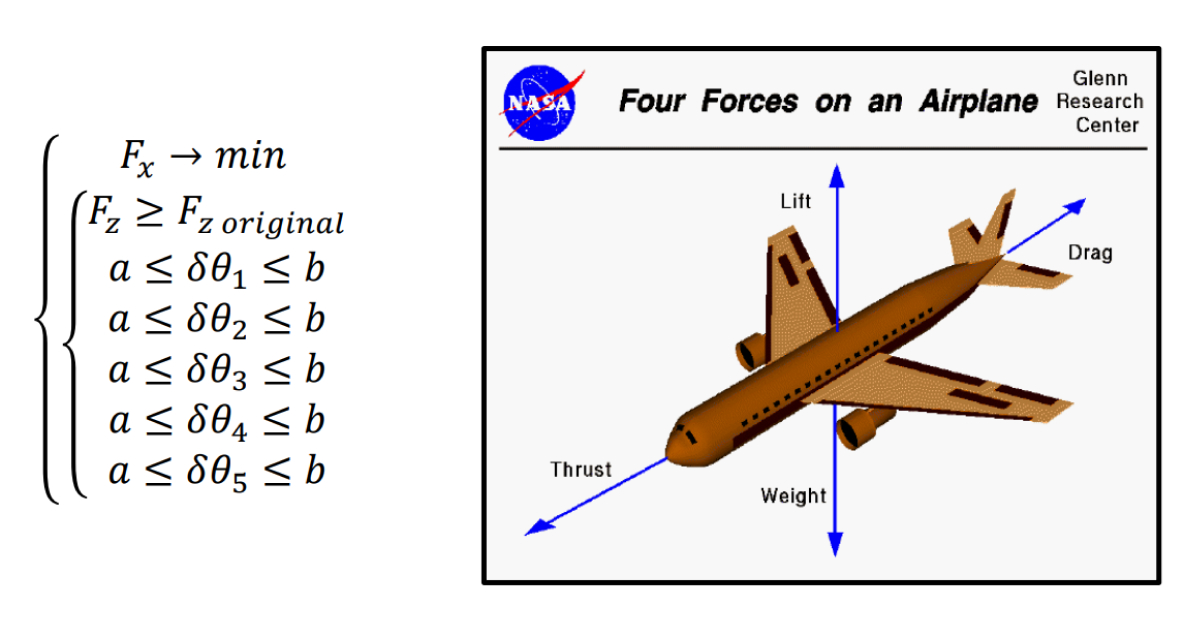

Like with any business, it's crucial for aerospace companies to keep costs down without compromising quality or service standards. Solving multiple tasks from various fields of engineering analysis (strength, aerodynamics, gas dynamics and combustion analysis, durability and reliability, control system modeling, electromagnetic analysis etc.) is challenging because their goals are often contradictory. Using collaborative engineering capabilities and multidisciplinary design optimization tools of pSeven products allows handling various complex problems simultaneously.

Optimization allows to get the best out of your design idea,

- Thierry Chevalier, Ex Chief Engineer Digital Product Development & Manufacturing at Airbus Group.

Related publications

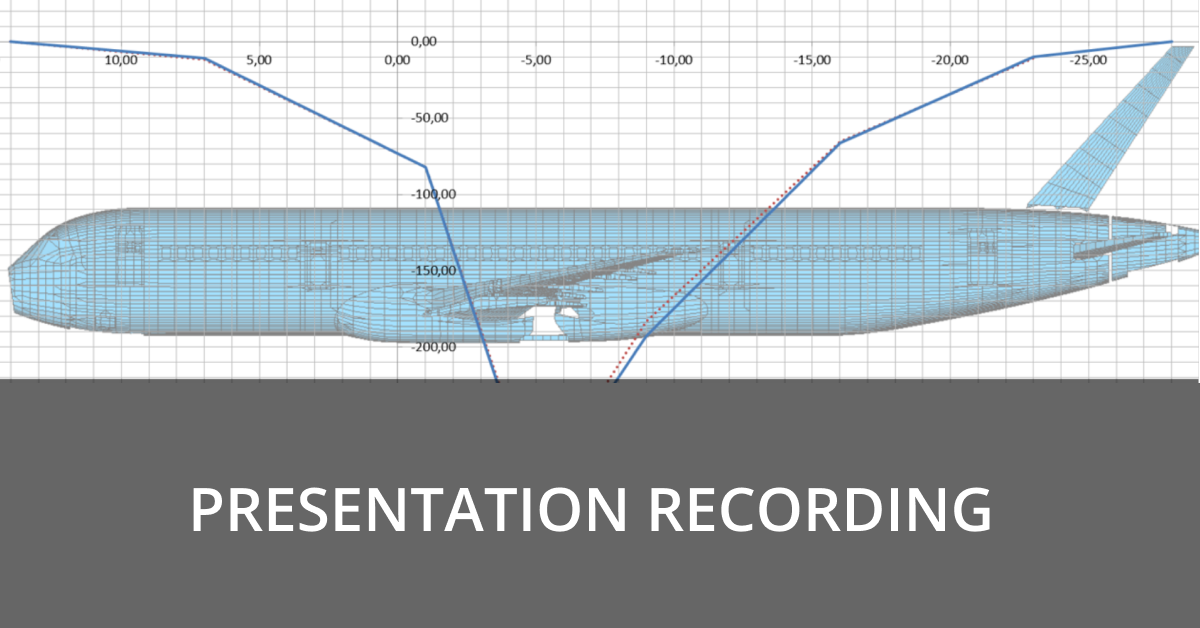

Aircraft wing geometry study in pSeven Enterprise

George Biryukov, Application Engineer, pSeven SAS

pSeven User Conference 2024

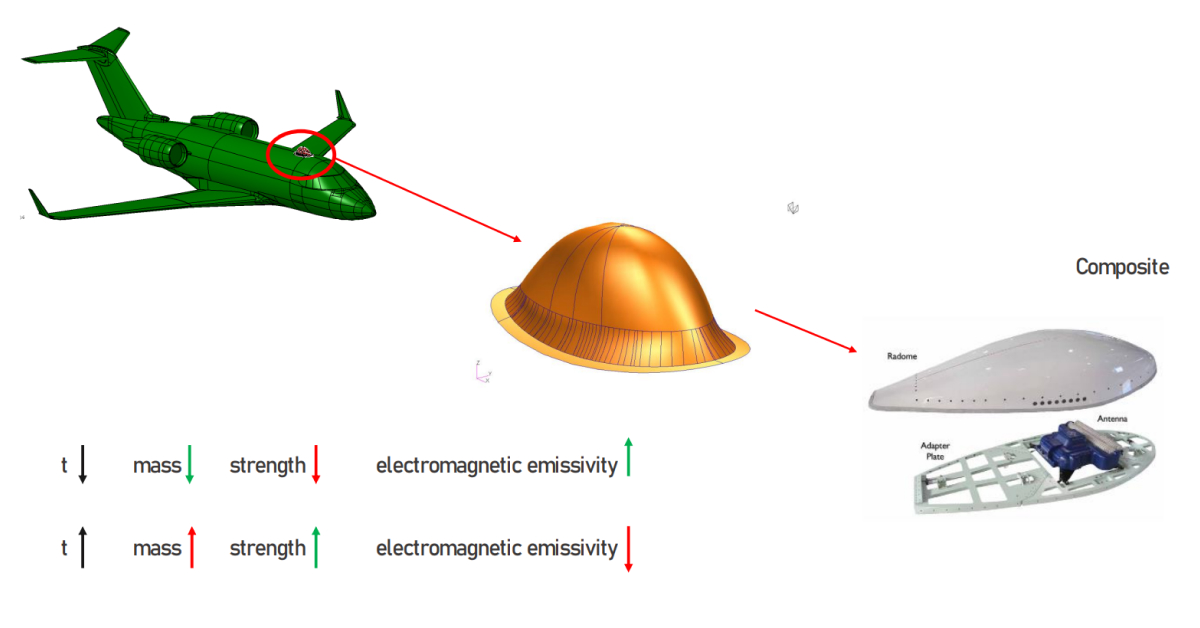

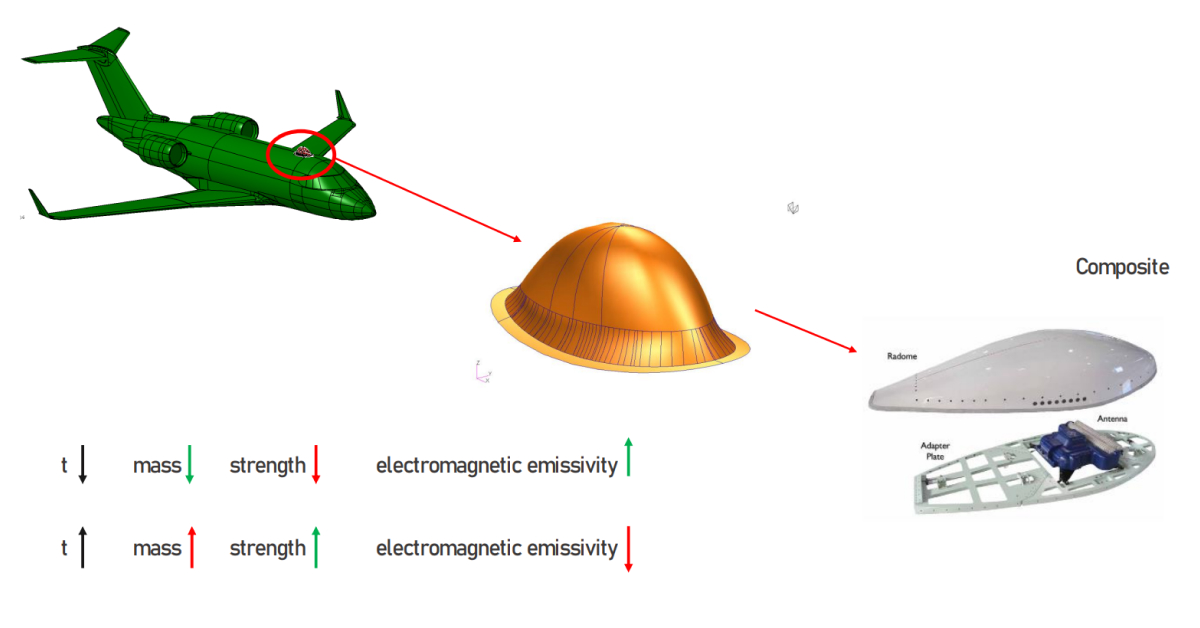

Multidisciplinary analysis and workflow automation of a parametric design of an aircraft antenna radome geometry

Ender Koç, General Manager, BİAS MÜHENDİSLİK

pSeven User Conference 2024

An MDO-based Methodology for Static Aeroelastic Scaling of Wings under Non-similar Flow

Joan Mas Colomer, Nathalie Bartoli, Thierry Lefebvre, Joaquim R. R. A. Martins & Joseph Morlier

Structural and Multidisciplinary Optimization

settings Use case

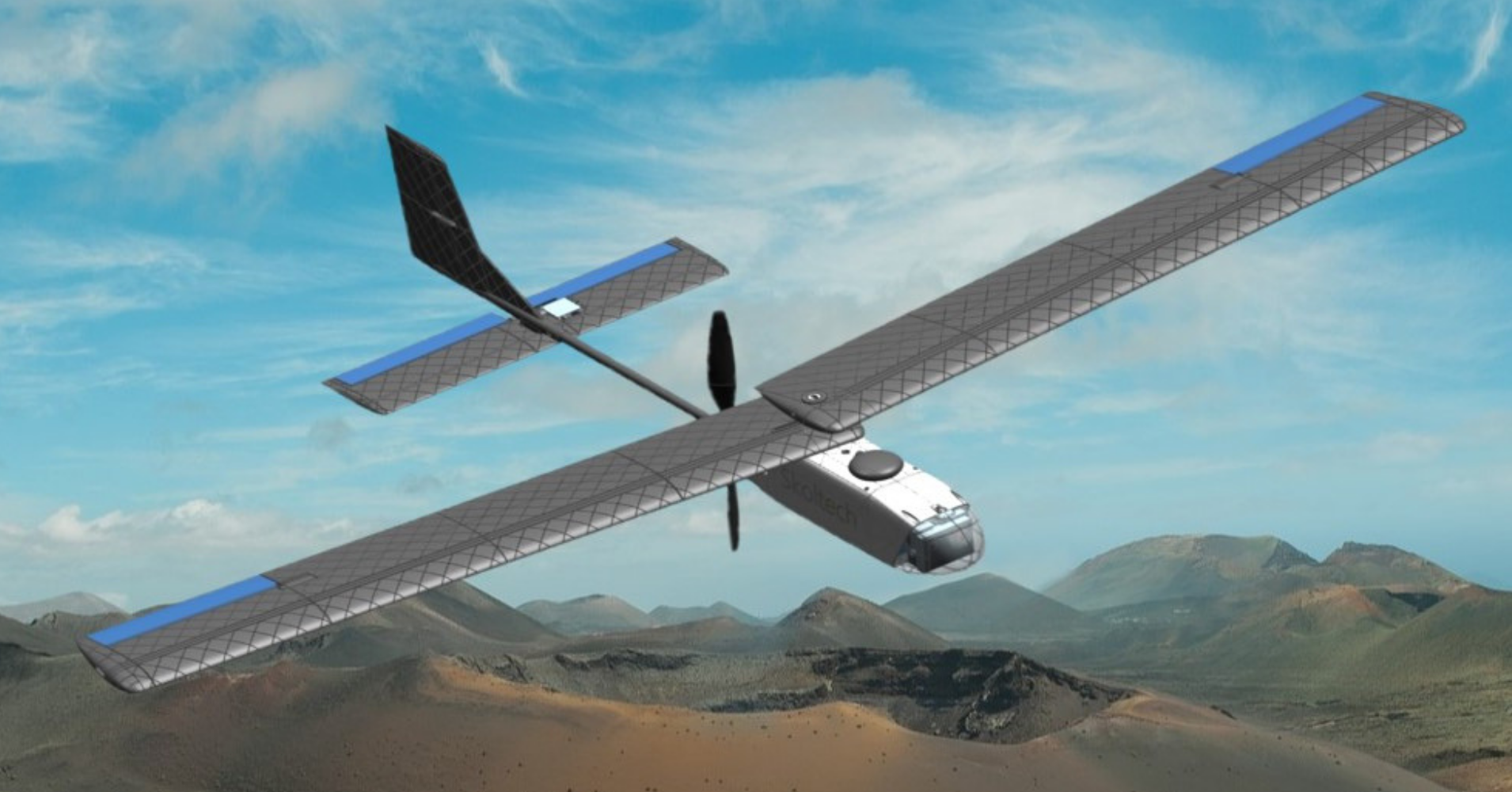

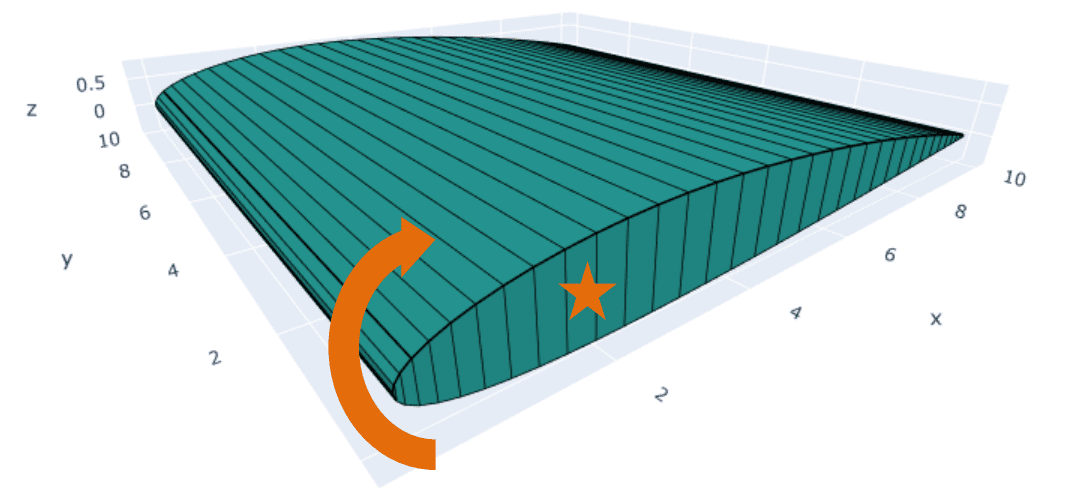

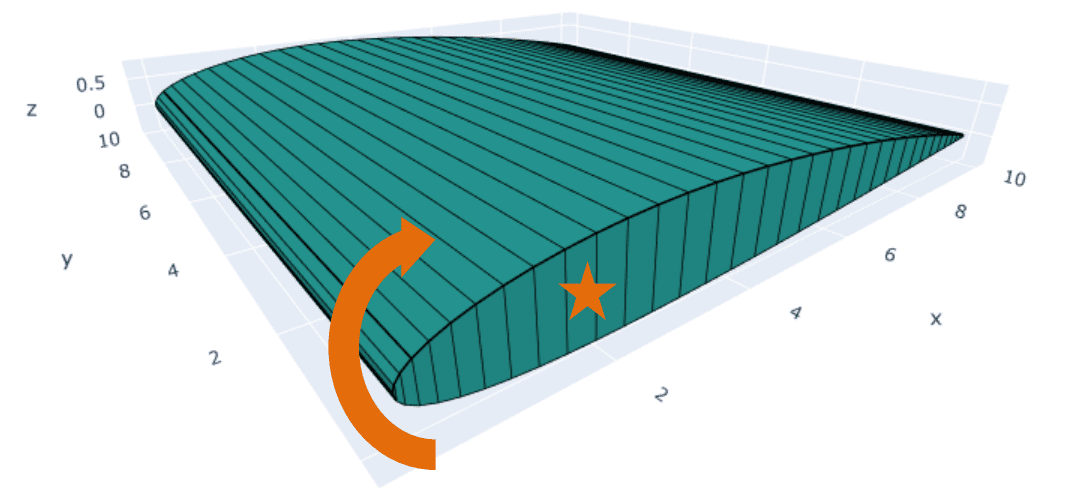

Collaborative work on aircraft wing design in pSeven Enterprise

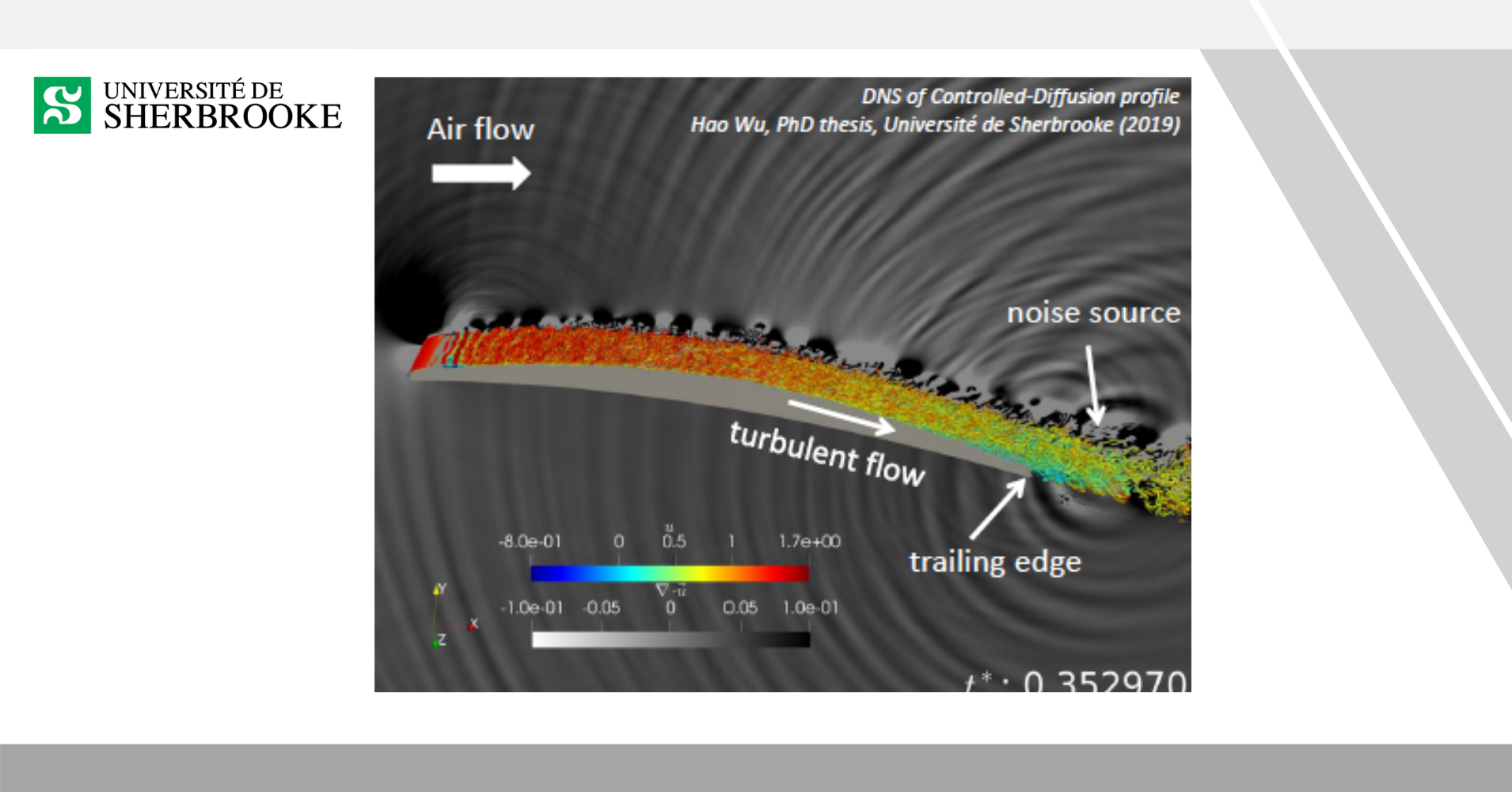

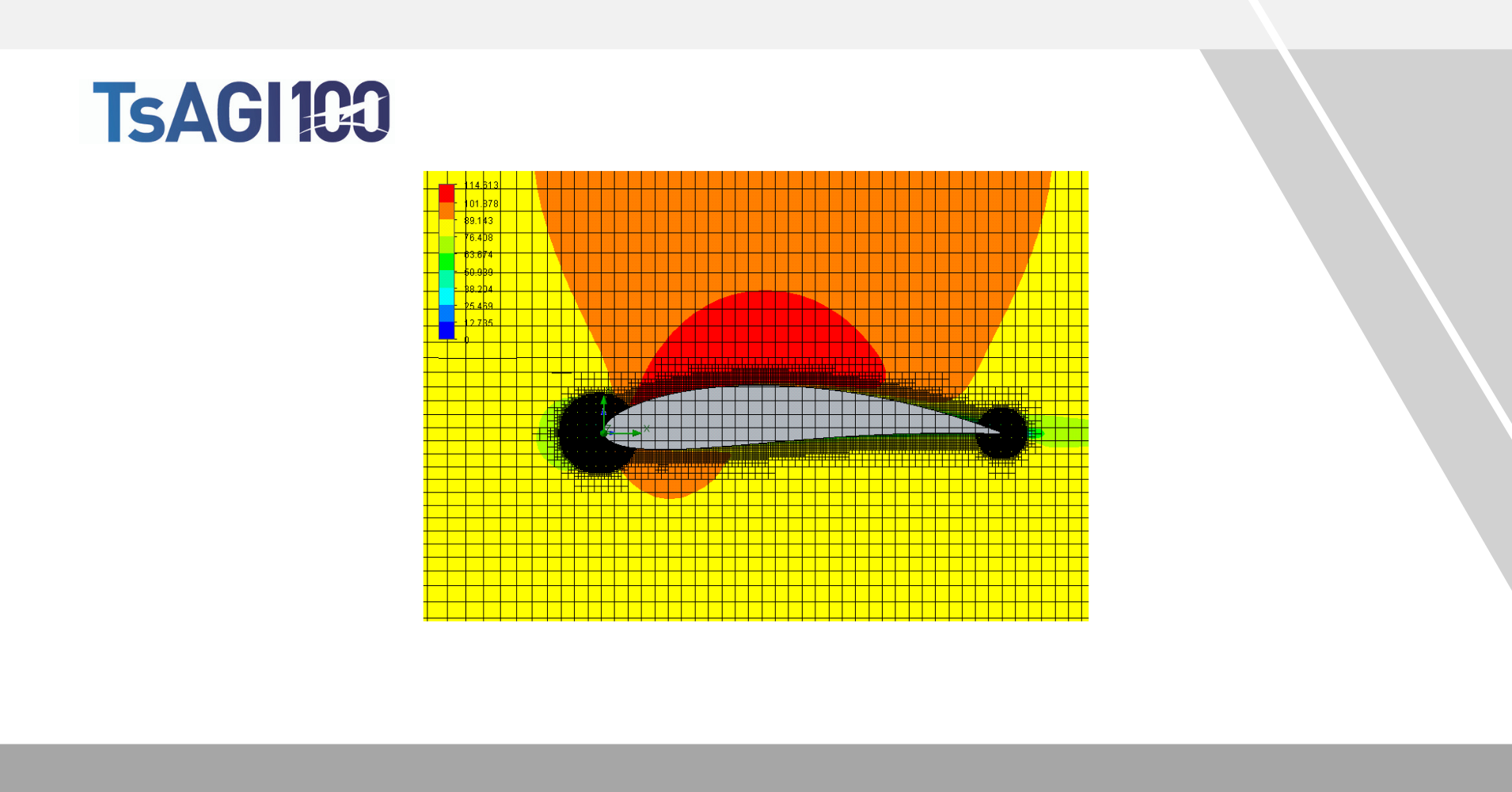

Designing an aircraft wing is a complex challenge. The behaviour of the wing in the flow is highly nonlinear and obtaining valid wing properties through simulation requires significant experience from an aerodynamics engineer. However, the design process does not conclude with a single iteration; it involves evaluating trade-offs between multiple aerodynamic parameters.

pSeven Enterprise addresses the complexities of aircraft wing design by automating optimization workflows, reducing human error and supporting collaborative work between different departments.

Predict product behaviour

and capture knowlege from data with fast ML models

AI and ML are revolutionizing the aerospace industry across various domains. They provide insights into the data by discovering new patterns and relations. pSeven solutions are delivered with predictive modeling capabilities – algorithms and techniques aimed to predict response values for new designs, accelerate complex simulations and capture knowledge from vast amounts of data. Predictive models can be used for single- and multi-objective optimization and uncertainty quantification, while SmartSelection technology provides automatic selection and adaptive tuning of algorithms for beginners.

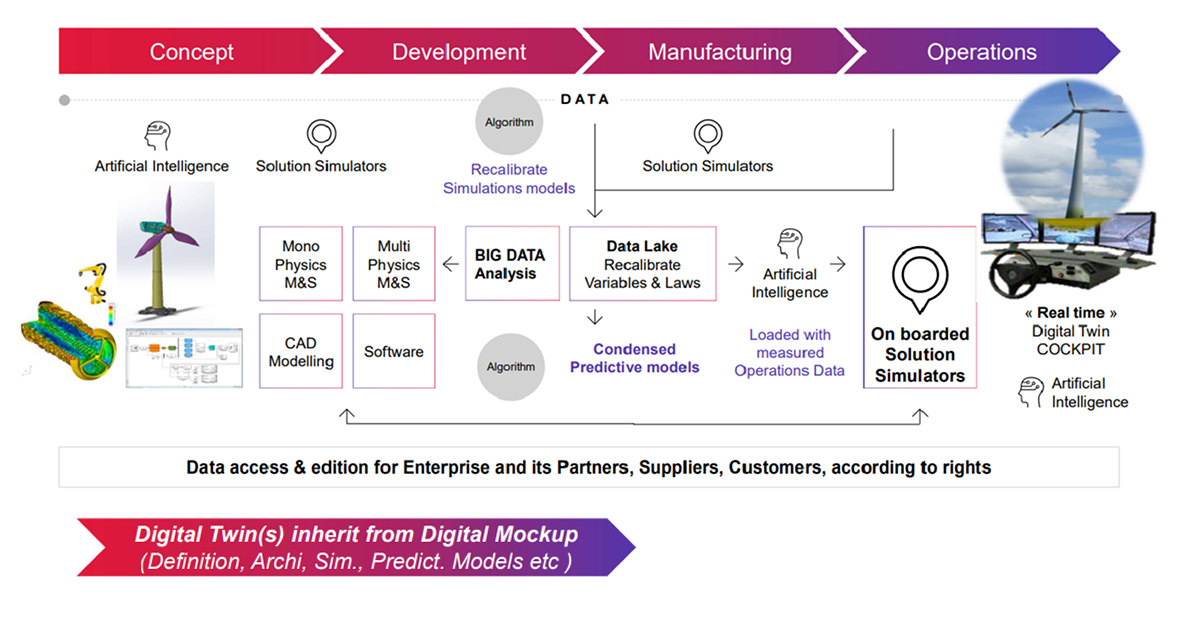

The platform ensures the production, deployment and management of digital twins at scale. pSeven Enterprise allows to assemble hybrid Digital Twins based on both predictive (ML) models trained on experimental data and simulation results. In addition, advanced optimization techniques provide more flexibility in the life cycle of the Digital Twin (calibration, uncertainty management, conditional behavior, fidelity adjustment etc.).

MACROS* (former name of pSeven Core) helps Airbus to perform its trade-off studies more efficiently across all development phases and to find more opportunities in the design of the future aircraft,

- Charles Champion, Executive Vice President Engineering, Airbus.

Related publications

Digital Twin to master systems across the whole lifecycle

Bruno Trebucq, Director Advisor R&D – Digital Twin, CGI

pSeven User Conference 2023

Recent progress in engineering design with MDO/AI

Joseph Morlier, Professor of Aerospace Engineering, ISAE-SUPAERO/ICA

pSeven User Conference 2022

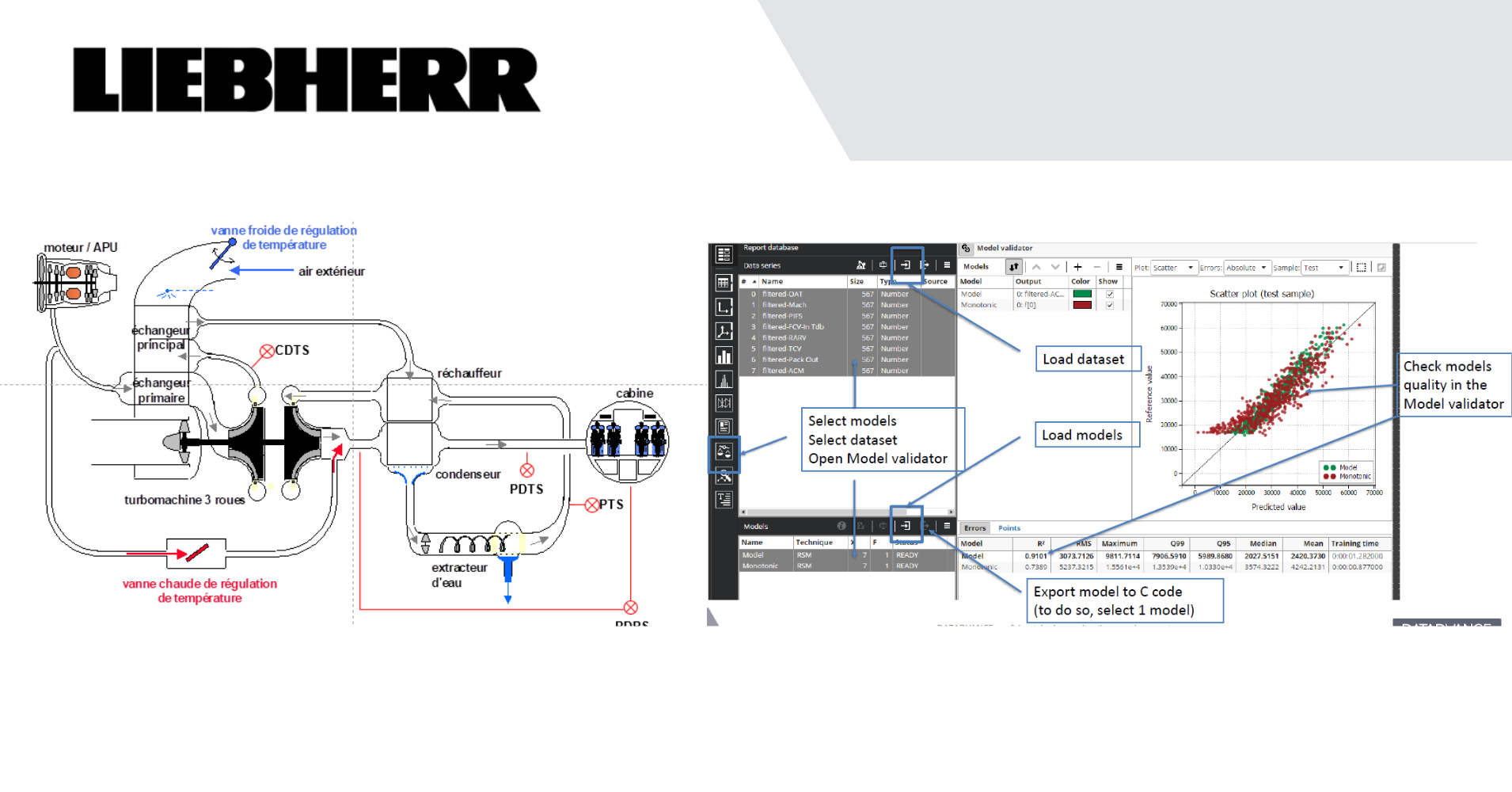

RSM surrogate model under monotonic constraint for enhanced system monitoring and control

Quentin Courjeau, Air Systems Engineer, Liebherr Aerospace

DATADVANCE User Conference 2021

Democratize simulation

with workflow-powered web apps

For a technology to have a significant impact, it must be affordable and scalable, ensuring widespread adoption. Achieving net-zero targets, increasing productivity and supporting digital transformation in aerospace requires a huge boost in technology consumption. Simulation methodologies must be democratized to reach the vast engineering population and be produced on a large enough scale to make a real difference.

With pSeven Enterprise, Methods & Tools department and advanced users can share their knowledge and simulation methodologies with other users across and outside the organization in a form of workflow-powered web apps that are stored in a centralized location called AppsHub. AppsHub helps to automate routine engineering tasks and democratizes the use of simulation at enterprise scale – all in your browser.

Embrace digital transformation

with collaborative engineering and accelerated SPDM adoption

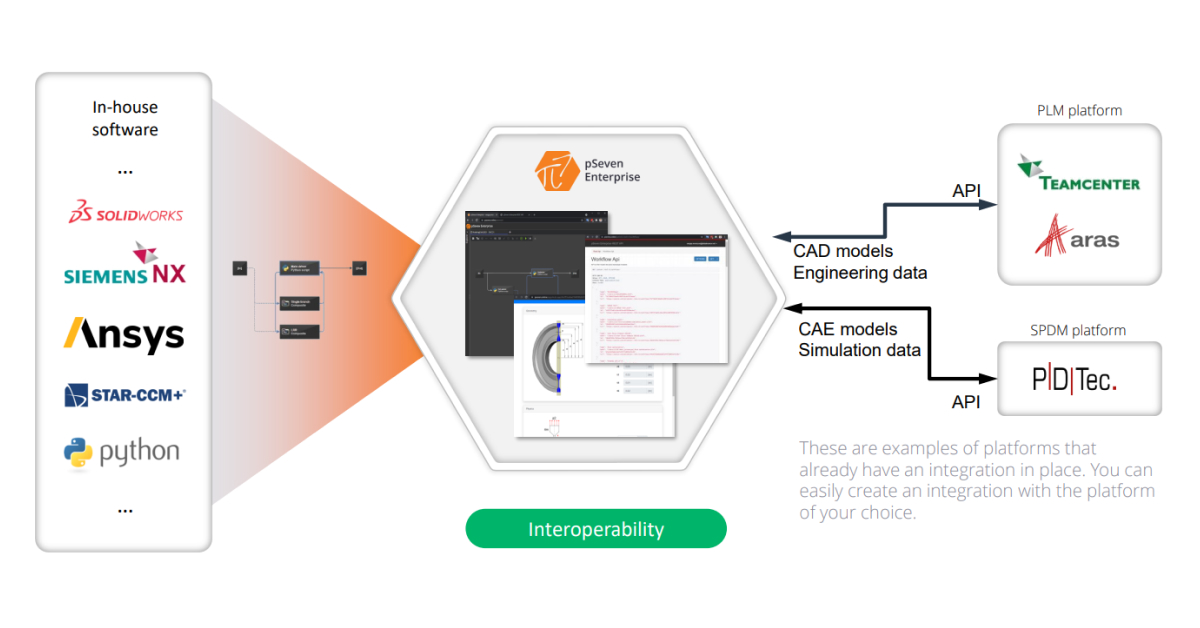

Faced with pressure to deliver more sustainable and efficient aircraft quickly, aerospace companies are embracing digital transformation. One of the challenges here are complex and outdated systems that can be difficult to integrate with newer digital ecosystems. SPDM systems are one of the drivers of digital transformation in aerospace as they improve collaboration across teams and streamline engineering workflows. Still, according to NAFEMS, the adoption of SPDM systems by simulation engineers is very low, at 1%-2%. One of the reasons is that it is very difficult for an SPDM system to establish a direct connection to the entire engineering software ecosystem that engineers, coming from all disciplines, used throughout the product development cycle.

Leveraging process modeling and integration framework in pSeven Enterprise accelerates SPDM deployment. It is able to remove the traditional technology lock of these SPDM platforms in terms of interoperability with engineering applications. It encapsulates hundreds of applications and micro-services in standard blocks and becomes a kind of universal connection to these applications for the SPDM platform.

Related publications

Enhancing engineering efficiency: the synergy of SPDM and PIDO integration

Laurent Chec, General director, pSeven SAS

NAFEMS World Congress 2025

Connecting simulation to enterprise digital thread with the help of collaborative engineering platforms and SPDM

Sandeepak Natu, Executive Consultant, CIMdata

pSeven User Conference 2024

Seamless integration of PDTec SPDM and pSeven for enhanced data storage solutions

Alexander Köppe, Technical Consultant, PDTec AG

pSeven User Conference 2024

Explore industrial use cases

Related publications

Collaborative Design and Optimization of the Aircraft Wing Geometry

Nina Moello, Application Engineer pSeven SAS

NAFEMS World Congress 2025

Aircraft wing geometry study in pSeven Enterprise

George Biryukov, Application Engineer, pSeven SAS

pSeven User Conference 2024

Multidisciplinary analysis and workflow automation of a parametric design of an aircraft antenna radome geometry

Ender Koç, General Manager, BİAS MÜHENDİSLİK

pSeven User Conference 2024

What's in the eBook?

done pSeven products description

done Application scenarios

done Selected industrial use cases