storm Solutions for Turbomachinery

The future of turbomachinery is being shaped by the need for greater efficiency and performance across various applications, for reducing environmental impact and for adaptability to a changing market landscape.

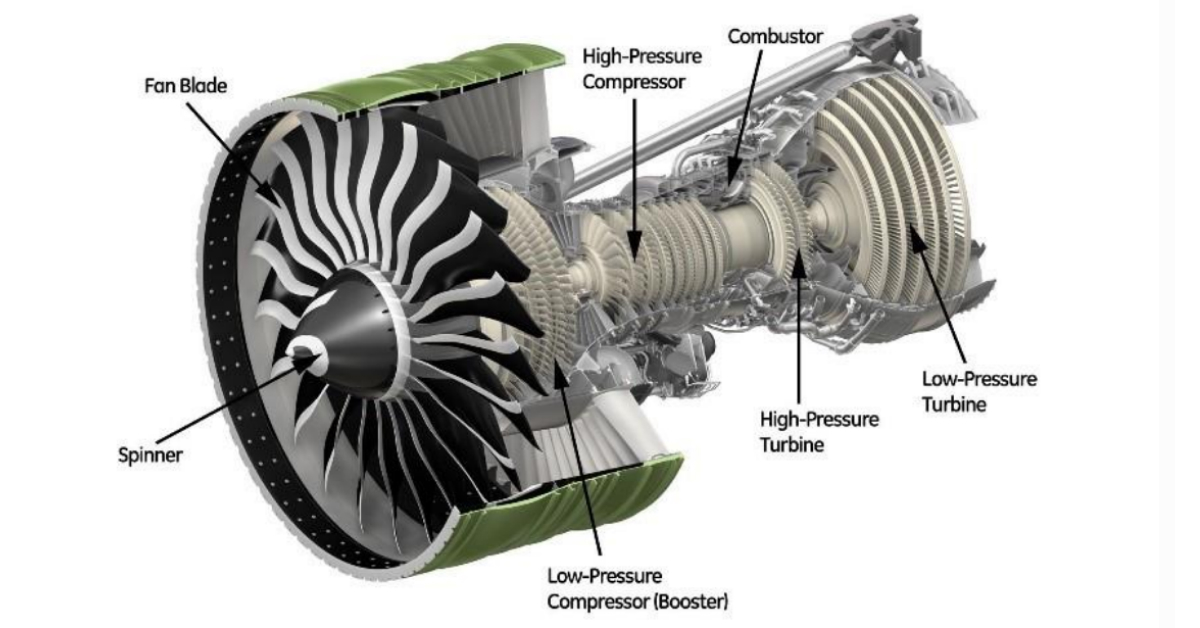

pSeven offers turbomachinery designers and simulation engineers a powerful collaborative environment for automating simulation workflows, reducing development costs, and improving the performance of open machines, such as propellers, windmills, and enshrouded fans, as well as closed machines, such as steam or water turbines and jet engines.

Adressing challenges

in the Turbomachinery industry

Manufacturers of rotating equipment appplied across different industries, such as aerospace, energy and marine, face a variety of challenges, including achieving higher efficiency, managing thermal stresses, reducing emissions of CO2 and NOx, and handling complex flow phenomena, particularly in high-pressure and high-speed environments. Furthermore, ensuring robustness against manufacturing imperfections and operating conditions is crucial, requiring advanced design and simulation techniques.

High-fidelity simulation and analysis software tools, such as those for computational fluid dynamics and structural mechanics, have become essential for addressing turbomachinery design challenges. The next step to further reduce design lead time and cost while improving product technical specs is to automate engineering processes and apply design exploration tools in a collaborative engineering environment.

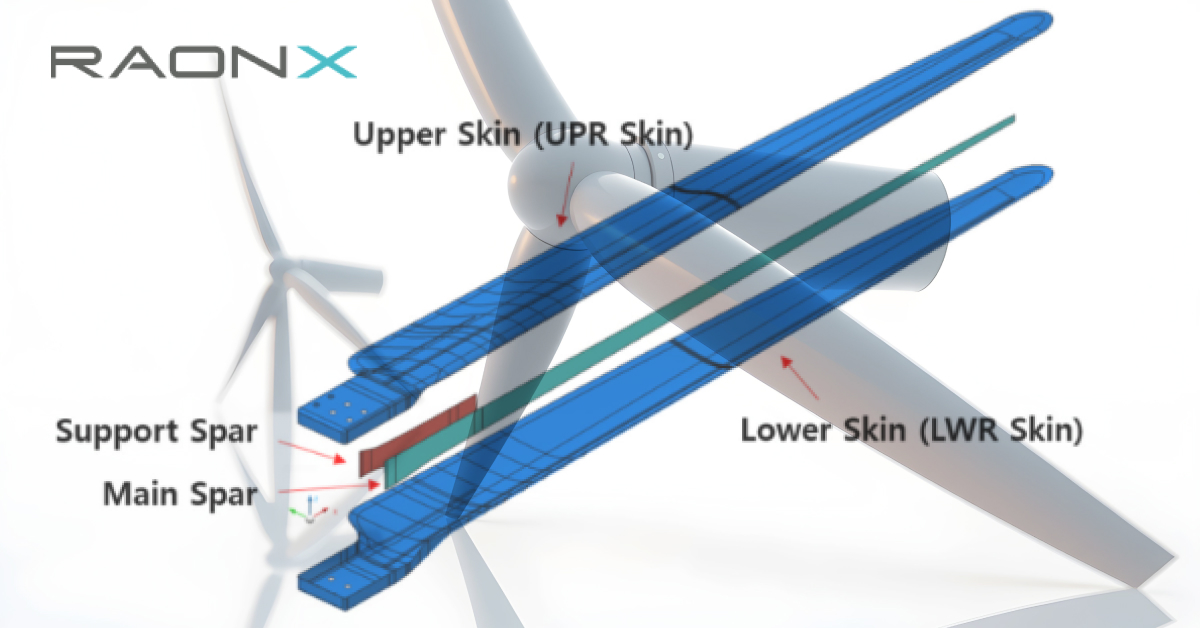

Users of pSeven products automate and speed-up simulation workflows, capture and transfer knowlege and apply design exploration to upgrade product performance and lower the development costs of various types of rotating equipment, such as steam turbines, fans and air compressors, marine propellers, wind turbines, pumps and more.

At ETN Global, we believe that by fostering open collaboration and aligning industry needs with emerging talent and technology, the turbomachinery sector can remain a competitive enabler of the energy transition.

- Giuseppe Tilocca, Energy & Turbomachinery Network (ETN) Global’s Technical Lead

Deliver innovative solutions faster and at lower cost

- Maximize efficiency, minimize mass and improve characteristics.

- Assemble digital prototypes as a basis of a digital twin.

Speed up engineering processes and reduce errors

- Capture complex engineering workflows.

- Reduce labor costs for routine tasks.

- Eliminate errors in data transfer.

Foster collaborationand formalize methodologies

- Unify the design methodologies and democratize simulations.

- Co-author and share simulation worflows server-side.

- Wrap workflows into web apps.

Design efficient and reliable rotating equipment

with Design Exploration tools

Design Exploration capabilities of the pSeven solutions allow for an efficient and quick search for compromises between conflicting demands for high efficiency and respect for mechanical constraints. These capabilities encompass Design of Experiments (DoE), multidisciplinary and multi-objective optimization and the rich family of Precictive Modeling techniques to speed up the simulations.

Below are some types of real-world monodisciplinary (CFD, structural, etc.) and multidisciplinary, e.g. coupled aero-thermo-mechanical, multi-objective design optimization problems that can be solved using pSeven solutions to maximize the efficiency, minimize the mass or improve other characteristics of turbomachinery components.

CFD

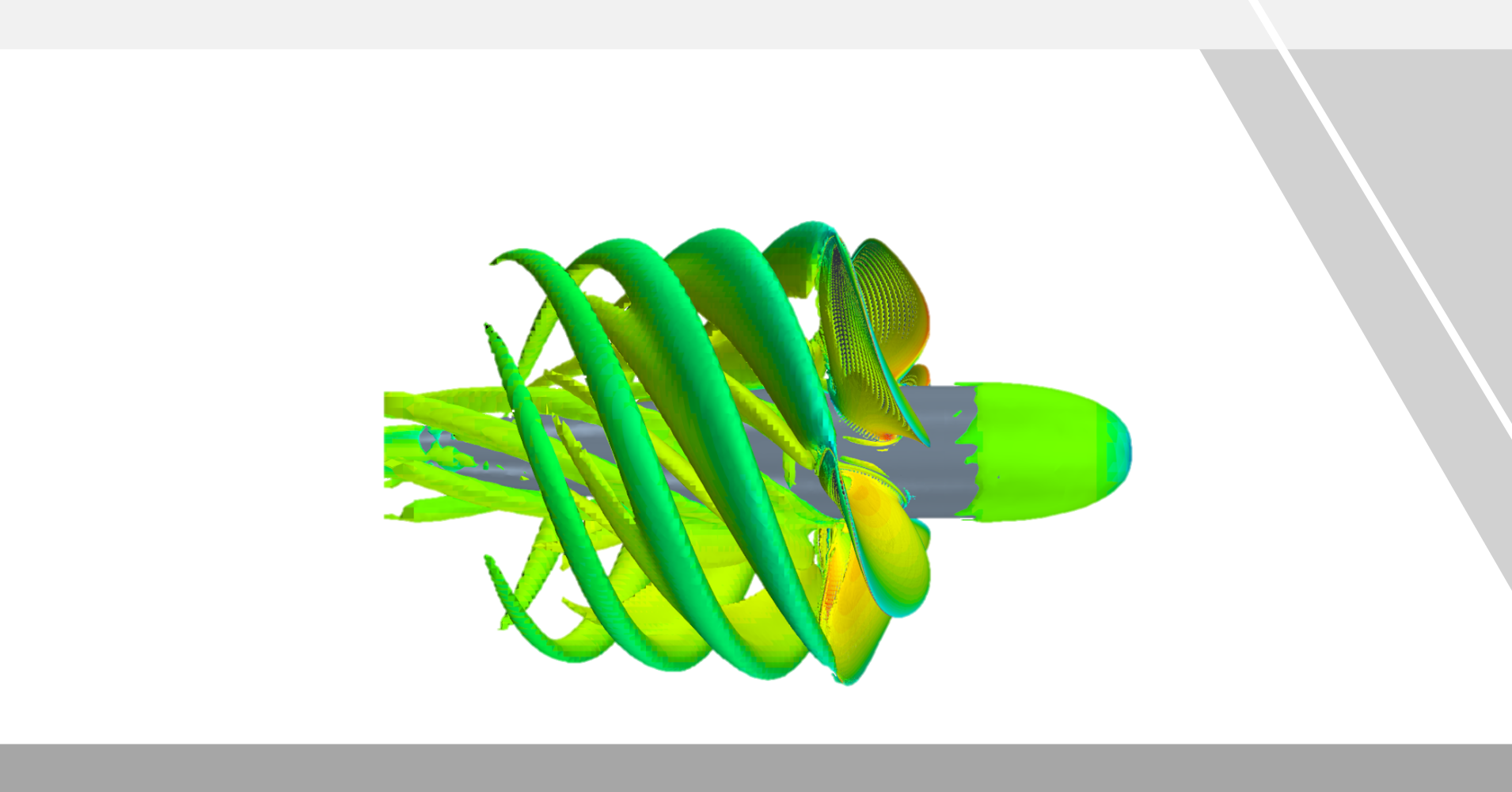

- Aerodynamic blade shape optimization of rotor compressor.

- Aerodynamic shape optimization of the last stage of steam turbine.

- Multidisciplinary fan optimization.

- Multistage aerodynamic gas path optimization.

- Robust optimization of coupled high and low pressure turbines.

- Oil pump volute optimization.

Structural

- Optimal design of:

- Low and high pressure turbine (LPT, HPT) disks taking into account non-stationary operating mode.

- Interlocking connection.

- Bolted joints (high pressures compressor rotor and low pressure turbine).

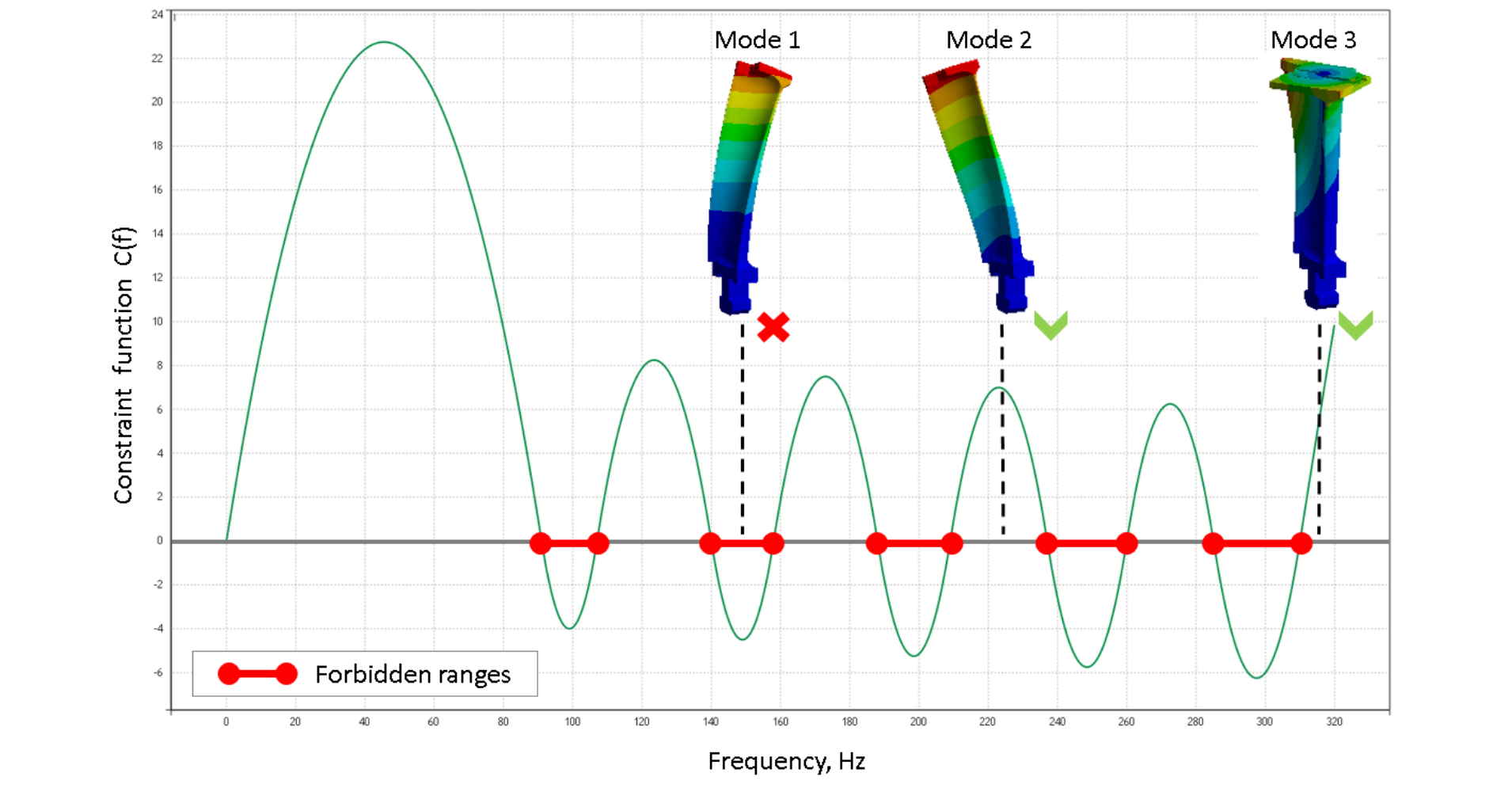

- Uncooled HPT blades taking into account the detuning from resonance modes.

- Optimization of compensation of shear forces to prevent axes misalignment between pump and electric motor

Speed up engineering processes and reduce errors

with powerful workflow engine

The complexity of turbomachinery design necessitates sophisticated design tools and simulation techniques. While these tools provide engineers with valuable insights into the performance measures of interest, they can be challenging and time-consuming to implement on a larger scale. Due to the large number of employees involved, data transfer becomes an issue. Employees must conduct different simulations and manage the exchanged data formats.

pSeven solutions helps turbomachinery engineers accelerate simulation workflows and avoid errors thanks to workflow automation capabilities. It allows users to capture complex engineering workflows involving external CAD/CAE systems. This is done by visually modeling every step of the process, including building geometry models, generating meshes, processing results, and exchanging data between different software. These workflows can be automated to run repetitive simulations with minimal user intervention, reused, shared and adapted for similar tasks or projects ensuring consistency and saving time.

Manufacturers of rotating equipment can easily integrate a whole variety of widely used in the industry tools into the multidisciplinary workflows:

- Ansys Workbench

- Ansys Mechanical

- Ansys LS-DYNA

- Ansys TurboGrid

- Ansys CFX

- Ansys Fluent

- AxSTREAM

- CFturbo

- Concepts NREC

- Numeca AutoGrid

- Numeca FINE™/Turbo

- PumpLinx

- Salome-Meca

- Simcenter STAR-CCM+

- Simcenter FLOEFD

- Other proprietary and in-house tools

settings Use case

Automated detuning of steam turbine rotor blades' eigenfrequencies away from critical areas

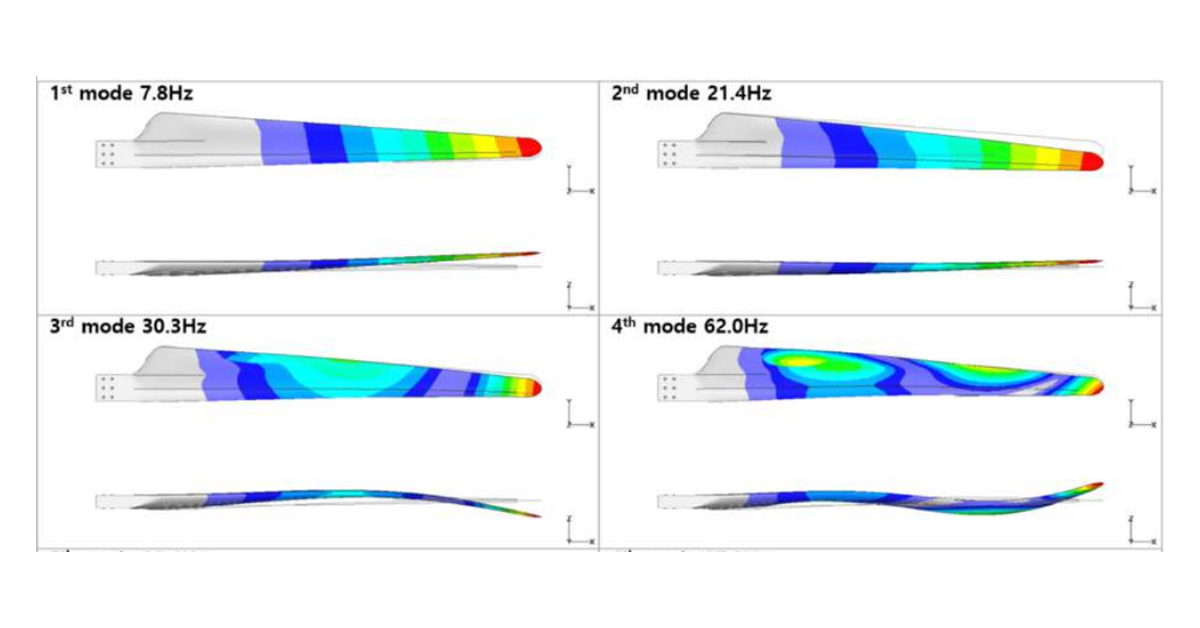

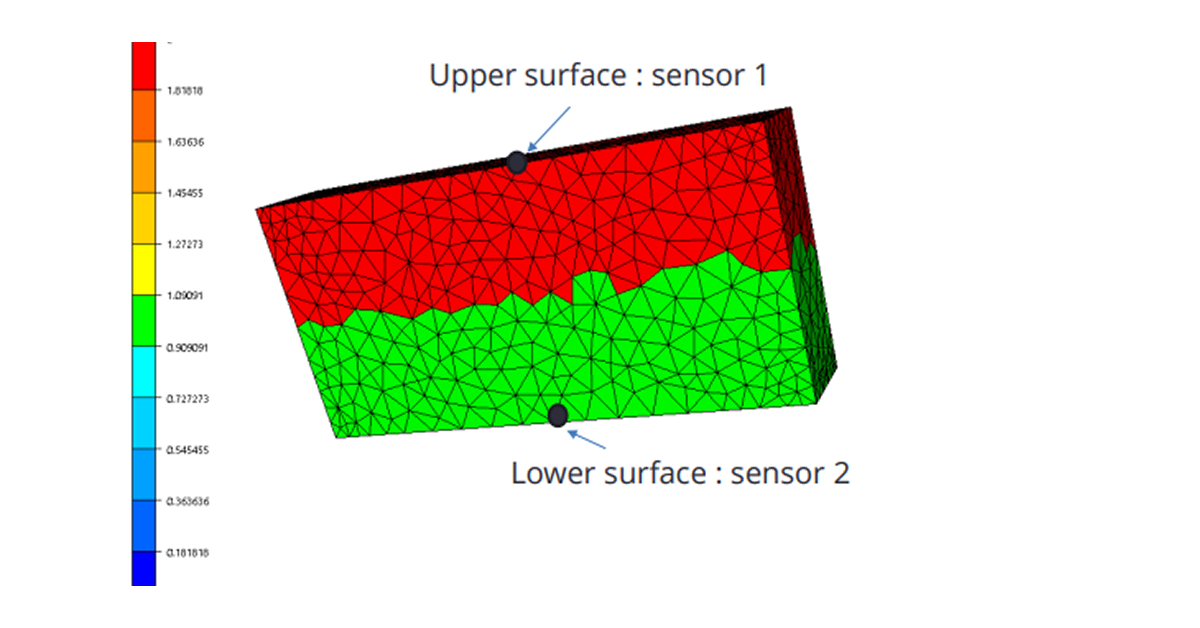

One of the most important issues to ensure operational safety is the tuning of rotor blades’ eigenfrequencies under operating conditions away from possible resonances with the rotation frequencies and pulsations of the steam flow. Within the described project, this task is solved using an automated module for determining the eigenfrequencies of the blades.

settings Use case

Automated construction of compressor performance maps in pSeven Enterprise

Compressor performance map is a graphical representation of compressor's efficiency, pressure ratio and surge limit across its operating range. It is an important tool for designers and engineers to analyze and optimize the compressor's performance under different operating conditions. One way to build a compressor map is to run a series of CFD simulations, but it requires a lot of manual work and rework of a simulation engineer. This use case demonstrates how the process of a compressor map construction can be automated using pSeven Enterprise and the benefits of such an approach.